We have two manufacturing units located in Sonipat, Haryana, covering a total area of over 116,000 square feet. We are regular manufacturer and supplier of products such as Braille signage, Fibre reinforced plastic (FRP) products and sanitary ware made of aluminum polymer composite.

In the turnkey furnishing of new railway coaches, we undertake the design and installation of interiors for various types of coaches. This includes different variants of Linke Hofmann Busch (LHB) coaches, self-propelled units such as vande bharat, self-propelled inspection coaches and overhead equipment coaches like the diesel electric tower car. We execute these projects at all major railway production facilities, including the Modern Coach Factory (MCF) in Raebareli, the Integral Coach Factory (ICF) in Chennai, and the Rail Coach Factory (RCF) in Kapurthala. Since 2017, we've successfully completed 28 projects of turnkey furnishing, delivering a total of 1,610 coaches.

.jpeg)

In the refurbishment, upgradation and conversion of old railway coaches, we focus on both LHB and ICF coaches. Our refurbishment operations include interior designs & redesigns, replacement of worn-out components with new upgraded Acme India Industries Limited 126 materials. The typical refurbishment cycle is 10-12 years (Source: D&B Industry report). Refurbishment of LHB and ICF coaches is carried out at designated railway workshops. Since securing our first upgradation contract in 2018, we have successfully refurbished and upgraded a total of 1,888 coaches till 31st of August 2025.

.jpeg)

-Toilet/BEFORE.jpeg)

-Toilet/AFTER.jpeg)

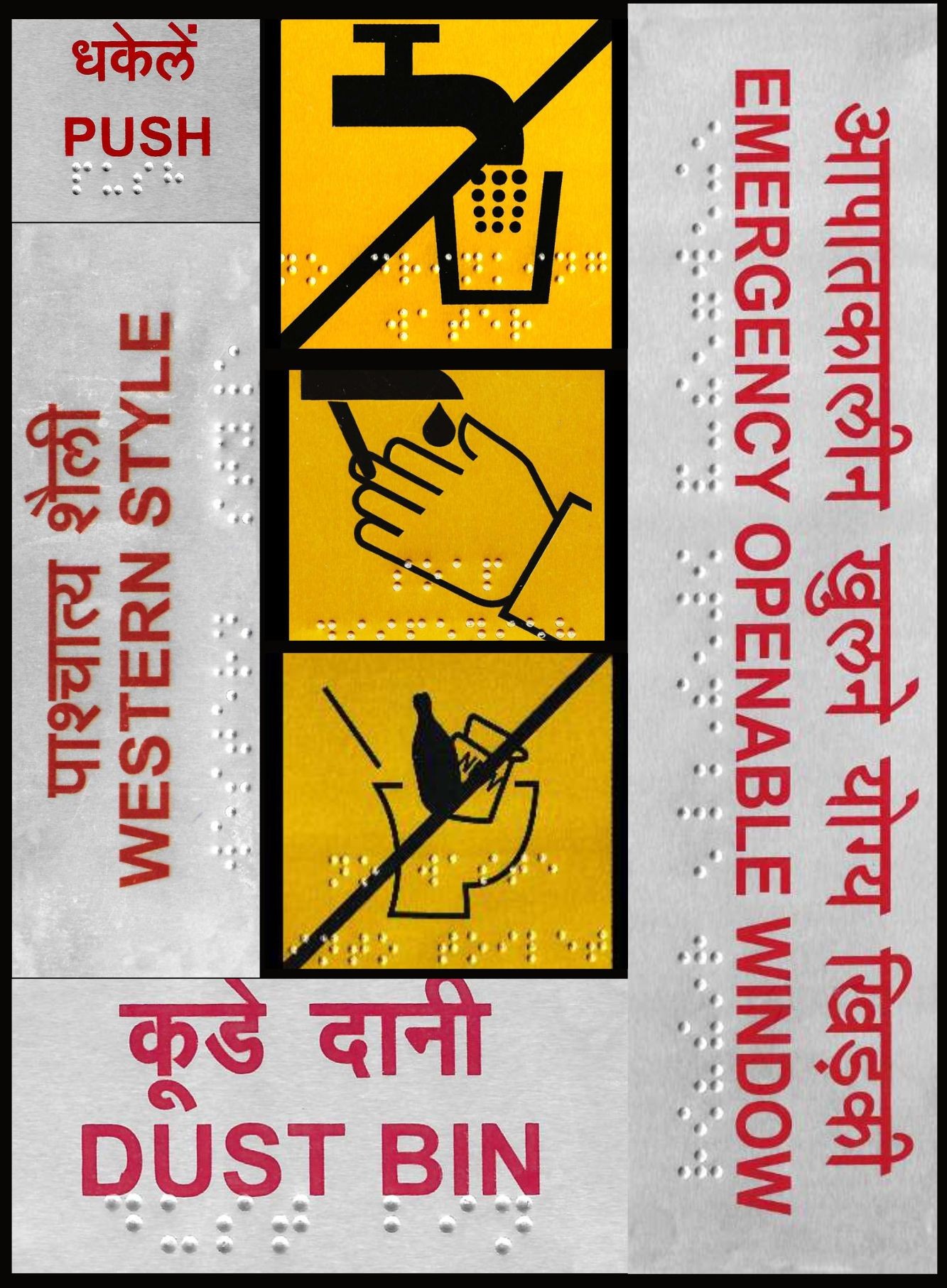

Our company specializes in the up-gradation and modernization of toilet facilities in railway coaches, both LHB and ICF. Till date, we have completed 10,948 units of toilet upgrades. These upgrades are designed to enhance hygiene, safety and passenger experience, aligning with the modernization efforts within the Indian Railways network.